■Application:

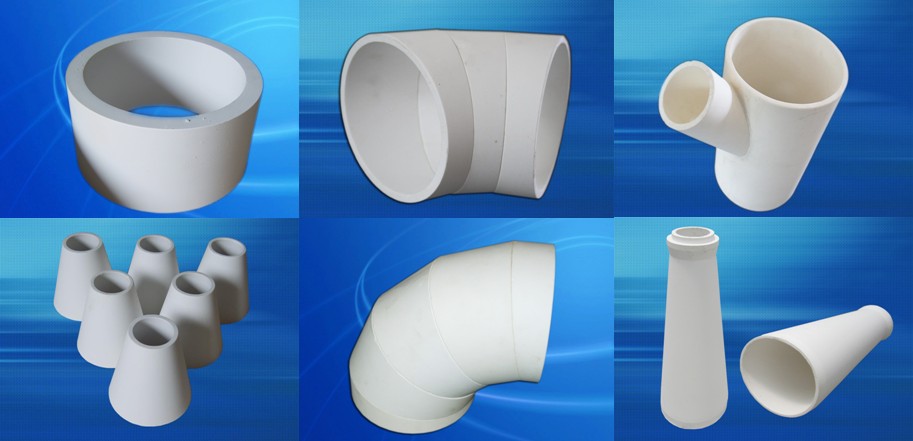

DuraAluTube® Alumina Ceramic Tube are developed for conveying big size hard materials. It is mainly used as

the lining in the pipeline of conveying ore fines, cement, coal and other hard material.

■ Regular sizes:

|

Specifications(mm) |

Outer Diameter(mm) |

Inner Diameter(mm) |

Thickness (mm) |

|

Φ25 |

Φ25 |

Φ10 |

7.5 |

|

Φ30 |

Φ30 |

Φ15 |

7.5 |

|

Φ40 |

Φ40 |

Φ20 |

10 |

|

Φ50 |

Φ50 |

Φ37 |

6.5 |

|

Φ65 |

Φ65 |

Φ52 |

6.5 |

|

Φ80 |

Φ80 |

Φ67 |

6.5 |

|

Φ100 |

Φ100 |

Φ84 |

8 |

|

Φ125 |

Φ125 |

Φ109 |

8 |

|

Φ150 |

Φ150 |

Φ134 |

8 |

|

Φ200 |

Φ200 |

Φ184 |

8 |

|

Φ250 |

Φ250 |

Φ230 |

10 |

Remark: the biggest OD up to 750mm is available. Other sizes are available upon request.

■ Technical Specification:

|

Technical Index |

DuraAluTube92 ® |

DuraAluTube95 ® |

DuraAluTube99 ® |

|

Al2O3 Content (%) |

≥92 |

≥95 |

≥99 |

|

Fe2O3 Content (%) |

≤0.2 |

≤0.15 |

≤0.1 |

|

Hardness (Mohs) |

9 |

9 |

9 |

|

water Absorption(%) |

≤0.02 |

≤0.02 |

≤0.01 |

|

density(g/cm3) |

≥3.60 |

≥3.65 |

≥3.75 |

■Packaging: In wooden box with net weight 20-24MT/20'FCL.

■Key benefits:

1. Superior wear resistance compared with other material. The service life is about 5 time longer than that of

alumina ceramic tile with the same thickness.

2.Excellent wear resistance against acid and alkali.

3. Excellent resistance against big hard material without breakage.

4. Smooth surface makes excellent flowability and avoid blacking the pipe system.

5.Reduce the frequency of maintenance to the facility, so as to reduce the cost and labor expense.

|