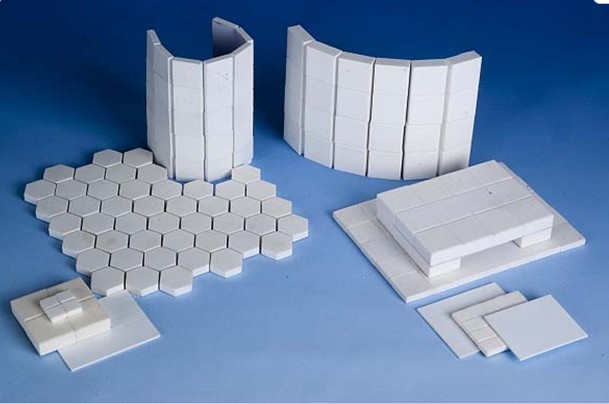

■ Application:

Suitable for any part of production system which need wear protection, including not only machinery such as

mills,cyclones and separators but also equipment for loading and transferring materials such as hoppers,

silos, pipes etc.

DuraAlu®wear resistant ceramics are widely used in power plant, mining and mineral processing, steel

making blast furnace, cement plant, and coal preparation etc.

■Specifications:

|

Products |

DuraAlu92 ® |

DuraAlu95 ® |

|

Aumina Content (%) |

92 +/-1 |

95 +/-1 |

|

Hardness (Mohs) |

9 |

9 |

|

Rate of Water Absorption(%) |

≤0.01 |

≤0.01 |

|

Fracture Toughness (Mpa) |

3.65 |

3.75 |

|

Bending Strength (Mpa) |

255 |

275 |

|

Bulk Density (g/cm3) |

≥3.60 |

≥3.65 |

■Regular sizes:

|

Size (mm) |

Shape |

Size (mm) |

Shape |

|

100×150×6/8/13/25/50 |

Plain & Weldable |

50×20×6/13/25 |

Plain & Weldable |

|

100×100×6/8/13/25/50 |

Plain & Weldable |

10×10×2/3/4/5 |

Mosaic |

|

100×75×6/8/13/25/ |

Plain & Weldable |

5020×20×4/6 |

Mosaic /Hex.cylinder |

|

100×25×6/8/13 |

Plain & Weldable |

Diameter 25×25 (height) |

Cylinder |

|

150×50×13/25/30/40/50/60/70 |

Plain or Weldable |

Diameter 32×32 (height) |

Cylinder |

■Packaging:

In carton box or PP-bag , packed in fumigated wooden pallet with net weight 20-24MT/20'FCL.

■Key benefits:

Excellent anti-wear and corrosion resistance.

Longer life than that of traditional wear protection material.

Avoid shutdown time and maximize the productivity of your plant.

|