|

■Application:

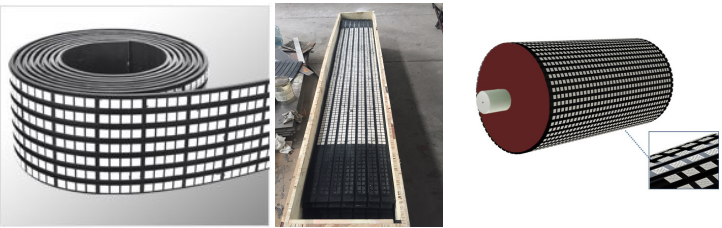

The DuraLagging® ceramic pulley lagging is constructed from hundreds of individual ceramic tiles molded into a

durable rubber backing.The ceramic lagging can significantly increase drive traction between the belt and the

pulley, which in turn reduces load and wear on the drive, belt, pulleys, bearings and take-up.

■Material Specification:

(1)Technical data sheet of ceramic:

DuraAlu92® DuraAlu95 ® DuraAlu97 ®

Alumina Content (%) ≥92 ≥95 ≥96

Viker Hardness (Hv50) ≥1088 ≥1150 ≥1247

Rate of Water Absorption ≤0.01 ≤0.01 ≤0.01

Fracture Toughness(Mpa0.5) 5.30 5.80 6.80

Bulk Density (g/cm3) ≥3.63 ≥3.65 ≥3.80

(2)Technical data sheet of rubber:

Tensile Strength >16MPa

Break Extension/Elongation >650%

Shore Hardness 60±5(adjustable)

Break permanent deformation 30%

Main composition Natural Rubber+SBR

Peel strength between rubber & ceramic >10 MPa

Best Working Temperature -20~150 ℃

■Regular Sizes:

Lagging Size Regular Width is up to 500mm,

Regular Length of each piece is up to 2600mm

Ceramic Size Regular size of ceramic: 20x20x7mm

Ceramic Shape: Mosaic with dimple,Plain mosaic, Arrow shape, diamond shape, around shape etc.

Rubber Thickness 13-17mm (or as per customer’s requests)

[Note:] Other sizes are available upon request.

■Key Feature and benefits:

• High quality ceramic with raised dimple with excellent abrasion resistance and improving the tracking

• Rubber compound blended with CN layer with outstanding adhesion to the ceramic, rubber and metal.

• Easy installation, saving labor cost

• Longer service life, extremely cost effective

|